Description

Short Pitch Precision Roller Chains

Short-pitch precision roller chains are intricately engineered chains specifically designed to deliver accurate and effective power transfer. These chains possess a compact pitch size, ensuring seamless operation and minimal backlash. They find widespread use across diverse industries, encompassing automotive, manufacturing, and automation sectors.

Through their superior craftsmanship and utilization of advanced manufacturing techniques, short-pitch precision roller chains exhibit exceptional tensile strength and robustness. They are engineered to endure heavy loads and withstand fatigue, guaranteeing dependable performance even in demanding scenarios.

Adhering to globally recognized standards such as ISO, ASME/ANSI, DIN, JIS, and others, these chains assure compatibility and interchangeability with a broad array of equipment and systems.

Whether employed in conveyor systems, machinery drives, or power transmission applications, short-pitch precision roller chains provide the essential reliability and precision necessary for smooth and efficient operations.

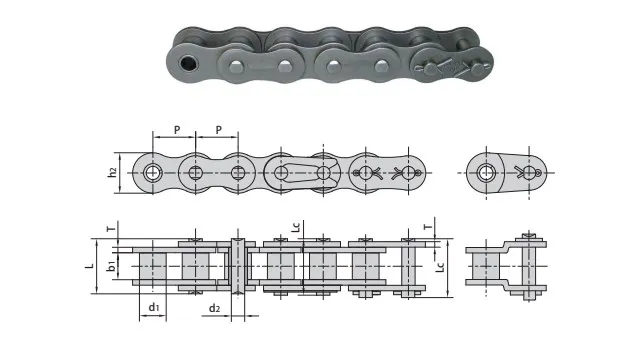

Simplex Roller Chains & Bush Chains

| DIN/ISO Chain No. |

ANSI Chain No. |

Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1 max |

b1 min |

d2 max |

L max |

Lc max | h2 max |

T max |

Q min |

Q0 | q | ||

| mm | mm | mm | mm | mm | mm | mm | mm | kN/lbf | kN | kg/m | ||

| *03C | *15 | 4.7625 | 2.48 | 2.38 | 1.62 | 6.10 | 6.90 | 4.30 | 0.60 | 1.80/409 | 2.0 | 0.08 |

| *04C-1 | *25 | 6.3500 | 3.30 | 3.18 | 2.31 | 7.90 | 8.40 | 6.00 | 0.80 | 3.50/795 | 4.6 | 0.15 |

| *06C-1 | *35 | 9.5250 | 5.08 | 4.77 | 3.58 | 12.40 | 13.17 | 9.00 | 1.30 | 7.90/1795 | 10.8 | 0.33 |

| 085-1 | 41 | 12.7000 | 7.77 | 6.25 | 3.58 | 13.75 | 15.00 | 9.91 | 1.30 | 6.67/1516 | 12.6 | 0.41 |

| 08A-1 | 40 | 12.7000 | 7.95 | 7.85 | 3.96 | 16.60 | 17.80 | 12.00 | 1.50 | 14.10/3205 | 17.5 | 0.62 |

| 10A-1 | 50 | 15.8750 | 10.16 | 9.40 | 5.08 | 20.70 | 22.20 | 15.09 | 2.03 | 22.20/5045 | 29.4 | 1.02 |

| 12A-1 | 60 | 19.0500 | 11.91 | 12.57 | 5.94 | 25.90 | 27.70 | 18.00 | 2.42 | 31.80/7227 | 41.5 | 1.50 |

| 16A-1 | 80 | 25.4000 | 15.88 | 15.75 | 7.92 | 32.70 | 35.00 | 24.00 | 3.25 | 56.70/12886 | 69.4 | 2.60 |

| 20A-1 | 100 | 31.7500 | 19.05 | 18.90 | 9.53 | 40.40 | 44.70 | 30.00 | 4.00 | 88.50/20114 | 109.2 | 3.91 |

| 24A-1 | 120 | 38.1000 | 22.23 | 25.22 | 11.10 | 50.30 | 54.30 | 35.70 | 4.80 | 127.00/28864 | 156.3 | 5.62 |

| 28A-1 | 140 | 44.4500 | 25.40 | 25.22 | 12.70 | 54.40 | 59.00 | 41.00 | 5.60 | 172.40/39182 | 212.0 | 7.50 |

| 32A-1 | 160 | 50.8000 | 28.58 | 31.55 | 14.27 | 64.80 | 69.60 | 47.80 | 6.40 | 226.80/51545 | 278.9 | 10.10 |

| 36A-1 | 180 | 57.1500 | 35.71 | 35.48 | 17.46 | 72.80 | 78.60 | 53.60 | 7.20 | 280.20/63682 | 341.8 | 13.45 |

| 40A-1 | 200 | 63.5000 | 39.68 | 37.85 | 19.85 | 80.30 | 87.20 | 60.00 | 8.00 | 353.80/80409 | 431.6 | 16.15 |

| 48A-1 | 240 | 76.2000 | 47.63 | 47.35 | 23.81 | 95.50 | 103.00 | 72.39 | 9.50 | 510.30/115977 | 622.5 | 23.20 |

*Bush chain: d1 in the table indicates the external diameter of the bush.

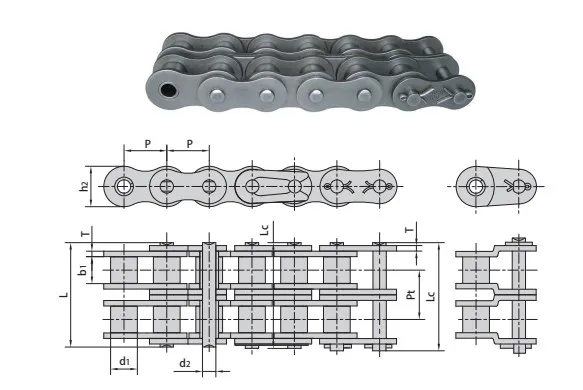

Duplex Roller Chains & Bush Chains

| DIN/ISO Chain No. |

ANSI Chain No. |

Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1 max |

b1 min |

d2 max |

L max |

Lc max | h2 max |

T max |

Pt | Q min |

Q0 | q | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN/lbf | kN | kg/m | ||

| *04C-2 | *25-2 | 6.350 | 3.30 | 3.18 | 2.31 | 14.5 | 15.0 | 6.00 | 0.80 | 6.40 | 7.00/1591 | 8.6 | 0.28 |

| *06C-2 | *35-2 | 9.525 | 5.08 | 4.77 | 3.58 | 22.5 | 23.3 | 9.00 | 1.30 | 10.13 | 15.80/3591 | 19.7 | 0.63 |

| 085-2 | 41-2 | 12.700 | 7.77 | 6.25 | 3.58 | 25.7 | 26.9 | 9.91 | 1.30 | 11.95 | 13.34/3032 | 16.9 | 0.81 |

| 08A-2 | 40-2 | 12.700 | 7.95 | 7.85 | 3.96 | 31.0 | 32.2 | 12.00 | 1.50 | 14.38 | 28.20/6409 | 35.9 | 1.12 |

| 10A-2 | 50-2 | 15.875 | 10.16 | 9.40 | 5.08 | 38.9 | 40.4 | 15.09 | 2.03 | 18.11 | 44.40/10091 | 58.1 | 2.00 |

| 12A-2 | 60-2 | 19.050 | 11.91 | 12.57 | 5.94 | 48.8 | 50.5 | 18.00 | 2.42 | 22.78 | 63.60/14455 | 82.1 | 2.92 |

| 16A-2 | 80-2 | 25.400 | 15.88 | 15.75 | 7.92 | 62.7 | 64.3 | 24.00 | 3.25 | 29.29 | 113.40/25773 | 141.8 | 5.15 |

| 20A-2 | 100-2 | 31.750 | 19.05 | 18.90 | 9.53 | 76.4 | 80.5 | 30.00 | 4.00 | 35.76 | 177.00/40227 | 219.4 | 7.80 |

| 24A-2 | 120-2 | 38.100 | 22.23 | 25.22 | 11.10 | 95.8 | 99.7 | 35.70 | 4.80 | 45.44 | 254.00/57727 | 314.9 | 11.70 |

| 28A-2 | 140-2 | 44.450 | 25.40 | 25.22 | 12.70 | 103.3 | 107.9 | 41.00 | 5.60 | 48.87 | 344.80/78364 | 427.5 | 15.14 |

| 32A-2 | 160-2 | 50.800 | 28.58 | 31.55 | 14.27 | 123.3 | 128.1 | 47.80 | 6.40 | 58.55 | 453.60/103091 | 562.4 | 20.14 |

| 36A-2 | 180-2 | 57.150 | 35.71 | 35.48 | 17.46 | 138.6 | 144.4 | 53.60 | 7.20 | 65.84 | 560.50/127386 | 695.0 | 29.22 |

| 40A-2 | 200-2 | 63.500 | 39.68 | 37.85 | 19.85 | 151.9 | 158.8 | 60.00 | 8.00 | 71.55 | 707.60/160818 | 877.4 | 32.24 |

| 48A-2 | 240-2 | 76.200 | 47.63 | 47.35 | 23.81 | 183.4 | 190.8 | 72.39 | 9.50 | 87.83 | 1020.60/213955 | 1255.3 | 45.23 |

*Bush chain: d1 in the table indicates the external diameter of the bush.

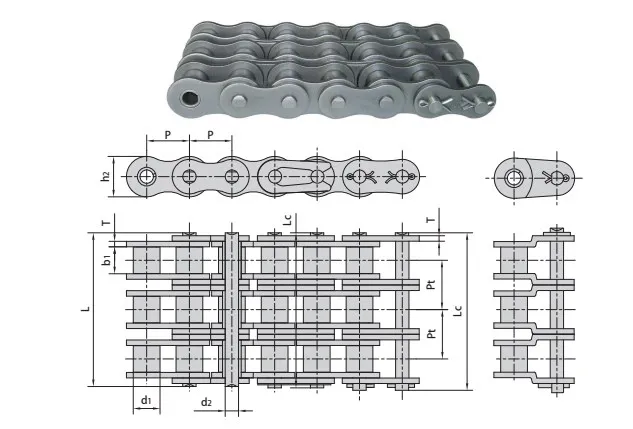

Triplex Roller Chains & Bush Chains

| DIN/ISO Chain No. |

ANSI Chain No. |

Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1 max |

b1 min |

d2 max |

L max |

Lc max | h2 max |

T max |

Pt | Q min |

Q0 | q | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN/lbf | kN | kg/m | ||

| *04C-3 | *25-3 | 6.350 | 3.30 | 3.18 | 2.31 | 21.0 | 21.5 | 6.00 | 0.80 | 6.40 | 10.5/2386 | 12.6 | 0.44 |

| *06C-3 | *35-3 | 9.525 | 5.08 | 4.77 | 3.58 | 32.7 | 33.5 | 9.00 | 1.30 | 10.13 | 23.7/5386 | 28.6 | 1.05 |

| 08A-3 | 40-3 | 12.700 | 7.95 | 7.85 | 3.96 | 45.4 | 46.6 | 12.00 | 1.50 | 14.38 | 42.3/9614 | 50.0 | 1.90 |

| 10A-3 | 50-3 | 15.875 | 10.16 | 9.40 | 5.08 | 57.0 | 58.5 | 15.09 | 2.03 | 18.11 | 66.6/15136 | 77.8 | 3.09 |

| 12A-3 | 60-3 | 19.050 | 11.91 | 12.57 | 5.94 | 71.5 | 73.3 | 18.00 | 2.42 | 22.78 | 95.4/21682 | 111.1 | 4.54 |

| 16A-3 | 80-3 | 25.400 | 15.88 | 15.75 | 7.92 | 91.7 | 93.6 | 24.00 | 3.25 | 29.29 | 170.1/38659 | 198.4 | 7.89 |

| 20A-3 | 100-3 | 31.750 | 19.05 | 18.90 | 9.53 | 112.2 | 116.3 | 30.00 | 4.00 | 35.76 | 265.5/60341 | 309.6 | 11.77 |

| 24A-3 | 120-3 | 38.100 | 22.23 | 25.22 | 11.10 | 141.4 | 145.2 | 35.70 | 4.80 | 45.44 | 381.0/86591 | 437.2 | 17.53 |

| 28A-3 | 140-3 | 44.450 | 25.40 | 25.22 | 12.70 | 152.2 | 156.8 | 41.00 | 5.60 | 48.87 | 517.2/117545 | 593.3 | 22.20 |

| 32A-3 | 160-3 | 50.800 | 28.58 | 31.55 | 14.27 | 181.8 | 186.6 | 47.80 | 6.40 | 58.55 | 680.4/154636 | 780.6 | 30.02 |

| 36A-3 | 180-3 | 57.150 | 35.71 | 35.48 | 17.46 | 204.4 | 210.2 | 53.60 | 7.20 | 65.84 | 840.7/191068 | 983.6 | 38.22 |

| 40A-3 | 200-3 | 63.500 | 39.68 | 37.85 | 19.85 | 223.5 | 230.4 | 60.00 | 8.00 | 71.55 | 1061.4/241227 | 1217.8 | 49.03 |

| 48A-3 | 240-3 | 76.200 | 47.63 | 47.35 | 23.81 | 271.3 | 278.6 | 72.39 | 9.50 | 87.83 | 1530.9/347932 | 1756.5 | 71.60 |

*Bush chain: d1 in the table indicates the external diameter of the bush.

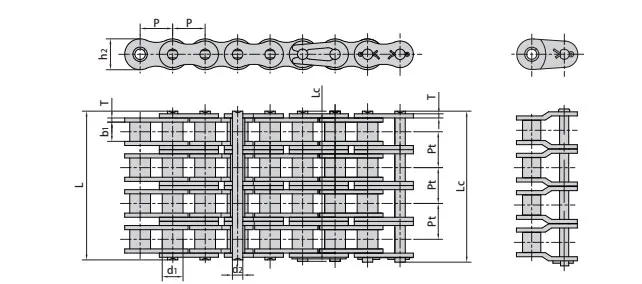

Multiple Strand Roller Chains

| EP Chain No. |

ANSI Chain No. |

Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1 max |

b1 min |

d2 max |

L max |

Lc max | h2 max |

T max |

Pt | Q min |

Q0 | q | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN/lbf | kN | kg/m | ||

| 08A-4 | 40-4 | 12.700 | 7.95 | 7.85 | 3.96 | 59.8 | 61.0 | 12.00 | 1.50 | 14.38 | 56.4/12687 | 62.04 | 2.57 |

| 10A-4 | 50-4 | 15.875 | 10.16 | 9.40 | 5.08 | 75.1 | 76.6 | 15.09 | 2.03 | 18.11 | 88.8/19976 | 97.68 | 4.30 |

| 12A-4 | 60-4 | 19.050 | 11.91 | 12.57 | 5.94 | 94.4 | 96.1 | 18.00 | 2.42 | 22.78 | 127.2/28614 | 139.92 | 6.21 |

| 16A-4 | 80-4 | 25.400 | 15.88 | 15.75 | 7.92 | 121.0 | 124.4 | 24.00 | 3.25 | 29.29 | 226.8/51020 | 249.48 | 10.37 |

| 20A-4 | 100-4 | 31.750 | 19.05 | 18.90 | 9.53 | 147.8 | 152.1 | 30.00 | 4.00 | 35.76 | 354/79635 | 389.40 | 15.60 |

| 24A-4 | 120-4 | 38.100 | 22.23 | 25.22 | 11.10 | 187.0 | 190.8 | 35.70 | 4.80 | 45.44 | 508/114278 | 558.80 | 23.56 |

| 08A-5 | 40-5 | 12.700 | 7.95 | 7.85 | 3.96 | 74.2 | 75.4 | 12.00 | 1.50 | 14.38 | 70.5/15859 | 77.55 | 3.19 |

| 10A-5 | 50-5 | 15.875 | 10.16 | 9.40 | 5.08 | 93.2 | 94.7 | 15.09 | 2.03 | 18.11 | 111/24970 | 122.10 | 5.37 |

| 12A-5 | 60-5 | 19.050 | 11.91 | 12.57 | 5.94 | 117.0 | 118.8 | 18.00 | 2.42 | 22.78 | 159/35768 | 174.90 | 7.75 |

| 16A-5 | 80-5 | 25.400 | 15.88 | 15.75 | 7.92 | 149.9 | 153.7 | 24.00 | 3.25 | 29.29 | 283.5/63775 | 311.85 | 12.96 |

| 20A-5 | 100-5 | 31.750 | 19.05 | 18.90 | 9.53 | 183.6 | 187.9 | 30.00 | 4.00 | 35.76 | 442.5/99543 | 486.75 | 19.46 |

| 24A-5 | 120-5 | 38.100 | 22.23 | 25.22 | 11.10 | 232.3 | 236.1 | 35.70 | 4.80 | 45.44 | 635/142848 | 698.50 | 29.40 |

| 08A-6 | 40-6 | 12.700 | 7.95 | 7.85 | 3.96 | 88.5 | 89.8 | 12.00 | 1.50 | 14.38 | 84.6/19031 | 93.06 | 3.83 |

| 10A-6 | 50-6 | 15.875 | 10.16 | 9.40 | 5.08 | 111.3 | 112.8 | 15.09 | 2.03 | 18.11 | 133.2/29964 | 146.52 | 6.43 |

| 12A-6 | 60-6 | 19.050 | 11.91 | 12.57 | 5.94 | 139.8 | 141.8 | 18.00 | 2.42 | 22.78 | 190.8/42921 | 209.80 | 9.31 |

| 16A-6 | 80-6 | 25.400 | 15.88 | 15.75 | 7.92 | 179.2 | 183.0 | 24.00 | 3.25 | 29.29 | 340.2/76530 | 374.22 | 15.50 |

| 20A-6 | 100-6 | 31.750 | 19.05 | 18.90 | 9.53 | 219.4 | 223.7 | 30.00 | 4.00 | 35.76 | 531/119452 | 584.10 | 23.36 |

| 24A-6 | 120-6 | 38.100 | 22.23 | 25.22 | 11.10 | 278.0 | 282.0 | 35.70 | 4.80 | 45.44 | 762/171417 | 838.20 | 35.30 |

| 08A-8 | 40-8 | 12.700 | 7.95 | 7.85 | 3.96 | 117.3 | 118.5 | 12.00 | 1.50 | 14.38 | 112.8/25375 | 124.08 | 5.11 |

| 10A-8 | 50-8 | 15.875 | 10.16 | 9.40 | 5.08 | 147.5 | 149.0 | 15.09 | 2.03 | 18.11 | 177.6/39952 | 195.36 | 8.59 |

| 12A-8 | 60-8 | 19.050 | 11.91 | 12.57 | 5.94 | 185.8 | 187.6 | 18.00 | 2.42 | 22.78 | 254.4/57229 | 279.84 | 12.37 |

| 16A-8 | 80-8 | 25.400 | 15.88 | 15.75 | 7.92 | 237.8 | 241.6 | 24.00 | 3.25 | 29.29 | 453.6/102040 | 498.96 | 20.67 |

| 20A-8 | 100-8 | 31.750 | 19.05 | 18.90 | 9.53 | 290.8 | 295.1 | 30.00 | 4.00 | 35.76 | 708/159270 | 778.80 | 31.14 |

| 24A-8 | 120-8 | 38.100 | 22.23 | 25.22 | 11.10 | 368.8 | 372.8 | 35.70 | 4.80 | 45.44 | 1016/228557 | 1176 | 47.07 |

Short Pitch Precision Roller Chains Application

The application of short-pitch precision roller chains is versatile and spans various industries and sectors. These chains are specifically designed to transmit power efficiently and reliably in a wide range of machinery and equipment. Here are some common applications of short-pitch precision roller chains:

- Conveyor Systems: Short-pitch precision roller chains are widely used in conveyor systems to transport materials or products. They ensure smooth and consistent movement, even when subjected to high loads and continuous operation.

- Manufacturing Machinery: These chains find application in manufacturing machinery, such as assembly lines, packaging equipment, and production machinery. They enable the synchronized movement of components, facilitating efficient production processes.

- Automation and Robotics: Short-pitch precision roller chains play a crucial role in automation and robotic systems. They are employed to transmit power and motion in robotic arms, CNC machines, and other automated equipment.

- Agricultural Machinery: In the field of agricultural machinery, short-pitch precision roller chains are utilized in equipment like combines, harvesters, and tractors. They facilitate the transmission of power and motion required for agricultural operations.

- Construction Machinery: Construction machinery, including excavators, loaders, and bulldozers, rely on short-pitch precision roller chains for power transmission. These chains endure heavy loads and provide reliable performance in demanding construction environments.

- Industrial Equipment: Short-pitch precision roller chains are used in a wide range of industrial equipment, such as printing presses, textile machines, and packaging machinery. They ensure efficient power transmission, enabling smooth operation and high productivity.

- Automotive Applications: These chains are found in automotive applications, including engine components, timing systems, and powertrain mechanisms. They provide reliable power transmission in vehicles, contributing to their overall performance.

Overall, short-pitch precision roller chains are integral components in various industries, where they enable the efficient and reliable transmission of power, motion, and mechanical functions in diverse machinery and equipment.