Description

Heavy-Duty Series Roller Chains

Discover Unrivaled Strength with Our Heavy-Duty Series Roller Chains!

Our heavy-duty series roller chains are engineered to deliver exceptional performance and durability in the most demanding industrial applications. Say goodbye to chain failures and downtime, and experience the power of reliability.

Key Features of Our Heavy-Duty Series Roller Chains:

- Extreme Load Capacity: Designed to handle heavy loads with ease, our chains provide reliable power transmission even under the most challenging conditions. Trust in their exceptional strength and durability.

- Robust Construction: Crafted from high-quality materials, our heavy-duty roller chains are built to last. Their robust design and superior components ensure long-lasting performance, reducing the need for frequent replacements.

- Enhanced Wear Resistance: With specialized heat treatment processes and precision engineering, our chains offer excellent wear resistance. They can withstand abrasive environments, extending the chain’s service life and reducing maintenance costs.

- Optimal Power Transmission: Experience smooth and efficient power transfer with our heavy-duty roller chains. Minimize friction, noise, and energy loss, and enjoy improved productivity and performance.

- Wide Range of Applications: Our heavy-duty series roller chains find applications across various industries, including mining, construction, forestry, and more. Versatile and adaptable, they excel in diverse industrial settings.

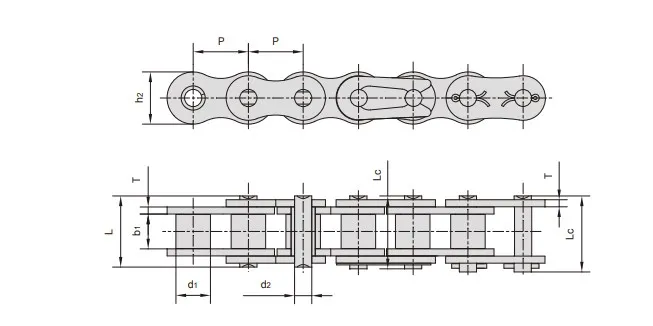

Simplex Roller Chains & Bush Chains

| ANSI/ISO Chain No. |

Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1 max |

b1 min |

d2 max |

L max |

Lc max | h2 max |

T max |

Q min |

Q0 | q | |

| mm | mm | mm | mm | mm | mm | mm | mm | kN/lbf | kN | kg/m | |

| *35H-1 | 9.525 | 5.08 | 4.77 | 3.58 | 13.3 | 14.3 | 9.00 | 1.50 | 7.9/1795 | 10.8 | 0.41 |

| 40H-1 | 12.700 | 7.95 | 7.85 | 3.96 | 18.8 | 19.9 | 12.00 | 2.03 | 14.1/3205 | 19.1 | 0.82 |

| 50H-1 | 15.875 | 10.16 | 9.40 | 5.08 | 22.1 | 23.4 | 15.09 | 2.42 | 22.2/5045 | 30.2 | 1.25 |

| 60H-1 | 19.050 | 11.91 | 12.57 | 5.94 | 29.2 | 31.0 | 18.00 | 3.25 | 31.8/7227 | 42.7 | 1.87 |

| 80H-1 | 25.400 | 15.88 | 15.75 | 7.92 | 36.2 | 37.7 | 24.00 | 4.00 | 56.7/12886 | 71.4 | 3.10 |

| 100H-1 | 31.750 | 19.05 | 18.90 | 9.53 | 43.6 | 46.9 | 30.00 | 4.80 | 88.5/20114 | 112.4 | 4.52 |

| 120H-1 | 38.100 | 22.23 | 25.22 | 11.10 | 53.5 | 57.5 | 35.70 | 5.60 | 127.0/28864 | 160.9 | 6.60 |

| 140H-1 | 44.450 | 25.40 | 25.22 | 12.70 | 57.6 | 62.2 | 41.00 | 6.40 | 172.4/39182 | 217.3 | 8.30 |

| 160H-1 | 50.800 | 28.58 | 31.55 | 14.27 | 68.2 | 73.0 | 47.80 | 7.20 | 226.8/51545 | 285.8 | 10.30 |

| 180H-1 | 57.150 | 35.71 | 35.48 | 17.46 | 75.9 | 81.6 | 53.60 | 8.00 | 281.0/63863 | 341.8 | 14.83 |

| 200H-1 | 63.500 | 39.68 | 37.85 | 19.85 | 86.6 | 93.5 | 60.00 | 9.50 | 353.8/80409 | 444.5 | 19.16 |

| 240H-1 | 76.200 | 47.63 | 47.35 | 23.81 | 109.6 | 115.9 | 72.30 | 12.70 | 510.3/115977 | 622.5 | 30.40 |

*Bush chain:d1 in the table indicates the external diameter of the bush

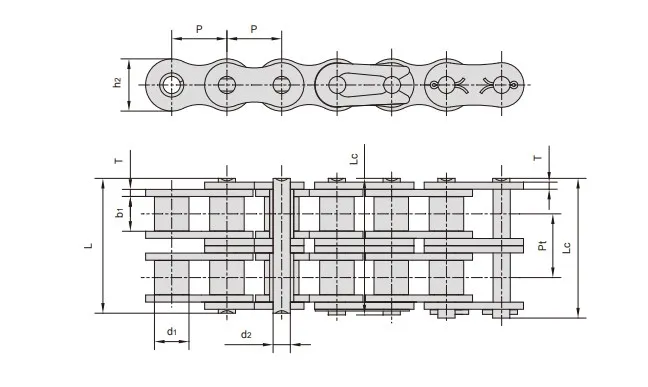

Duplex Roller Chains

| ANSI/ISO Chain No. |

Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1 max |

b1 min |

d2 max |

L max |

Lc max | h2 max |

T max |

Pt | Q min |

Q0 | q | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN/lbf | kN | kg/m | |

| 60H-2 | 19.050 | 11.91 | 12.57 | 5.94 | 55.3 | 57.1 | 18.00 | 3.25 | 26.11 | 63.6/14455 | 84.5 | 3.71 |

| 80H-2 | 25.400 | 15.88 | 15.75 | 7.92 | 68.8 | 70.3 | 24.00 | 4.00 | 32.59 | 113.4/25773 | 145.3 | 6.15 |

| 100H-2 | 31.750 | 19.05 | 18.90 | 9.53 | 82.7 | 86.0 | 30.00 | 4.80 | 39.09 | 177.0/40227 | 225.9 | 9.03 |

| 120H-2 | 38.100 | 22.23 | 25.22 | 11.10 | 102.4 | 106.4 | 35.70 | 5.60 | 48.87 | 254.0/57727 | 322.7 | 13.13 |

| 140H-2 | 44.450 | 25.40 | 25.22 | 12.70 | 109.8 | 114.4 | 41.00 | 6.40 | 52.20 | 344.8/78364 | 437.7 | 16.60 |

| 160H-2 | 50.800 | 28.58 | 31.55 | 14.27 | 130.1 | 134.9 | 47.80 | 7.20 | 61.90 | 453.6/103091 | 571.6 | 20.20 |

| 180H-2 | 57.150 | 35.71 | 35.48 | 17.46 | 146.5 | 155.6 | 53.60 | 8.00 | 69.16 | 562/127726 | 680.0 | 29.20 |

| 200H-2 | 63.500 | 39.68 | 37.85 | 19.85 | 164.9 | 171.8 | 60.00 | 9.50 | 78.31 | 707.6/160818 | 894.9 | 38.11 |

| 240H-2 | 76.200 | 47.63 | 47.35 | 23.81 | 212.6 | 223.1 | 72.30 | 12.70 | 101.22 | 1000/227270 | 1200.0 | 60.50 |

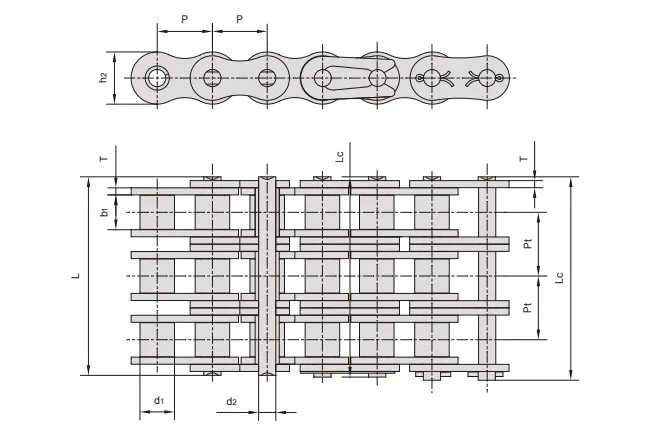

Triplex Heavy-Duty Roller Chains

| ANSI/ISO Chain No. |

Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1 max |

b1 min |

d2 max |

L max |

Lc max | h2 max |

T max |

Pt | Q min |

Q0 | q | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN/lbf | kN | kg/m | |

| 60H-3 | 19.050 | 11.91 | 12.57 | 5.94 | 81.4 | 83.2 | 18.00 | 3.25 | 26.11 | 95.4/21682 | 113.9 | 5.54 |

| 80H-3 | 25.400 | 15.88 | 15.75 | 7.92 | 101.4 | 102.9 | 24.00 | 4.00 | 32.59 | 170.1/38659 | 203.5 | 9.42 |

| 100H-3 | 31.750 | 19.05 | 18.90 | 9.53 | 121.8 | 125.1 | 30.00 | 4.80 | 39.09 | 265.5/60341 | 314.8 | 12.96 |

| 120H-3 | 38.100 | 22.23 | 25.22 | 11.10 | 151.2 | 155.2 | 35.70 | 5.60 | 48.87 | 381.0/86591 | 444.7 | 19.64 |

| 140H-3 | 44.450 | 25.40 | 25.22 | 12.70 | 162.0 | 166.6 | 41.00 | 6.40 | 52.20 | 517.2/117545 | 598.4 | 24.90 |

| 160H-3 | 50.800 | 28.58 | 31.55 | 14.27 | 192.0 | 196.8 | 47.80 | 7.20 | 61.90 | 680.4/154636 | 787.3 | 30.10 |

| 180H-3 | 57.150 | 35.71 | 35.48 | 17.46 | 215.7 | 224.8 | 53.60 | 8.00 | 69.16 | 843/191589 | 1011.0 | 44.10 |

| 200H-3 | 63.500 | 39.68 | 37.85 | 19.85 | 243.2 | 250.1 | 60.00 | 9.50 | 78.31 | 1061.4/241227 | 1228.2 | 57.06 |

| 240H-3 | 76.200 | 47.63 | 47.35 | 23.81 | 313.8 | 324.3 | 72.30 | 12.70 | 101.22 | 1500/340905 | 1650.0 | 91.00 |

Non-standard Heavy Duty Roller Chains

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Ultimate tensile strength | Weight per meter | |

| P | d1 max |

b1 min |

d2 max |

L max |

Lc max | h2 max |

t/T | Q min |

q | |

| mm | mm | mm | mm | mm | mm | mm | mm | kN/lbf | kg/m | |

| 04BH | 6.000 | 4.00 | 2.80 | 1.85 | 8.4 | 9.4 | 5.0 | 0.90 | 5.00/1136 | 0.14 |

| *06BH | 9.525 | 6.35 | 5.72 | 3.58 | 14.4 | 15.4 | 8.2 | 1.60 | 11.25/2557 | 0.51 |

| 08AHF1 | 12.700 | 7.95 | 10.00 | 3.96 | 21.0 | 22.2 | 12.0 | 2.03 | 13.80/3136 | 0.88 |

| 08BH | 12.700 | 8.51 | 7.85 | 4.45 | 18.8 | 19.9 | 11.8 | 2.03 | 20.60/4682 | 0.79 |

| 10BH | 15.875 | 10.16 | 9.65 | 5.08 | 20.2 | 21.6 | 14.7 | 1.85 | 25.00/5681 | 1.03 |

| 12BH | 19.050 | 12.07 | 11.68 | 5.94 | 25.2 | 26.8 | 16.0 | 2.42 | 40.00/9091 | 1.45 |

| 12BHF1 | 19.050 | 12.07 | 11.68 | 6.10 | 25.0 | 27.2 | 16.5 | 2.50 | 44.00/10000 | 1.46 |

| 12BHF2 | 19.050 | 12.07 | 13.30 | 6.10 | 28.8 | 30.3 | 16.5 | 2.80 | 35.00/7954 | 1.72 |

| 12BHF3 | 19.050 | 12.07 | 13.50 | 5.72 | 28.8 | 30.3 | 16.5 | 2.80 | 35.00/7954 | 1.71 |

| 12BV | 19.050 | 12.07 | 11.68 | 6.10 | 24.5 | 26.5 | 16.0 | 2.42 | 36.00/8182 | 1.43 |

| 60HV | 19.050 | 11.91 | 12.57 | 5.94 | 29.2 | 31.0 | 18.0 | 3.25 | 40.00/9090 | 2.00 |

| 16BH | 25.400 | 15.88 | 17.02 | 8.90 | 35.7 | 38.9 | 24.1 | 4.00/3.1 | 80.00/18182 | 3.11 |

| 16BHF3 | 25.400 | 15.88 | 12.70 | 8.90 | 31.6 | 35.0 | 24.1 | 4.00/3.1 | 80.00/18182 | 2.90 |

| 24BH | 38.100 | 25.40 | 25.40 | 14.63 | 58.6 | 63.4 | 36.2 | 7.50/6.0 | 225.00/51136 | 9.00 |

| 24BHF2 | 38.100 | 25.40 | 25.40 | 14.63 | 57.8 | 62.2 | 37.0 | 7.20/6.0 | 225.40/51226 | 9.06 |

| 24BHF5 | 38.100 | 25.40 | 25.40 | 14.63 | 64.6 | 69.1 | 36.2 | 9.00/7.5 | 270.00/61344 | 10.60 |

*Straight side plates

Choose Quality, Choose Reliability

At EPT, we take pride in delivering top-quality heavy-duty roller drive chains. Our commitment to excellence means you can trust our chains to deliver the performance and durability you need for your critical operations.

Maximize your productivity, minimize downtime, and experience the power of our heavy-duty roller drive chains today. Don’t compromise when it comes to power transmission—choose our reliable and robust chains for your industrial applications.